TECHNOLOGY

PROBLEM

Powering Digital Industrial Technologies in Remote Locations is Incredibly Challenging.

While the O&G industry is driving toward net zero GHG emissions in its operations, it is simultaneously installing advanced digital technologies at well sites and along pipelines, to improve the efficiency and safety of those operations, and is increasingly electrifying control systems to eliminate methane-emitting devices. These initiatives require even more electricity and more reliable power sources.

Existing technologies for providing power in remote environments require tradeoffs among cost, emissions, scalability, efficiency, and reliability. The oil and gas industry urgently needs a clean, highly reliable, and scalable power source for providing off-grid electric power. RTT’s mETS squarely meets these requirements.

Emissions

The oil & gas industry is under immense pressure to decarbonize their operations. Combustion generators add up to 60 tons of CO2 to the environment each year for each kilowatt generated.

Reliability

Operators have long experienced high maintenance and frequent failures of incumbent power generation solutions, resulting in high operating costs and unplanned downtime.

Connectivity

Most current remote power solutions lack connectivity and smart functionality–“must haves” in today’s digital world.

Scalable

Solar and TEGs are not readily scalable to meet increasing demand for automation and digitalization – key elements of most operating efficiency strategies.

SOLUTIONS

Reliable, Scalable, Zero-Emission Power Generation Driven by excess gas pressure

REVOLUTION Turbine Technologies’ (RTT) clean power generation solution meets remote power needs through smart waste energy recovery.

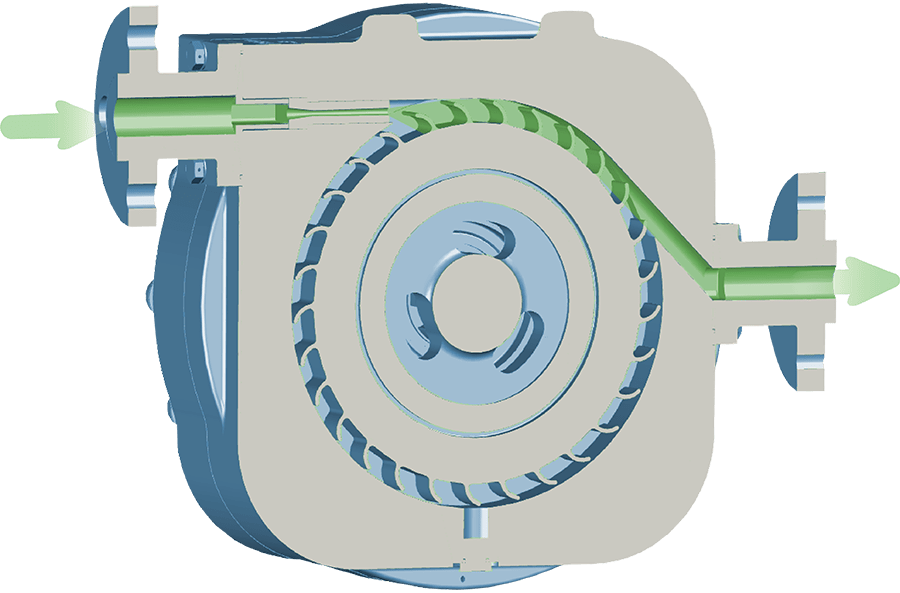

The micro-Expansion Turbine System (mETS) generates power using excess gas pressure, so nothing is burned or vented, and no CO2 or methane is released. Engineered specifically for highly efficient operation in challenging remote environments where extreme reliability, zero-touch remote operation, and size are crucial.

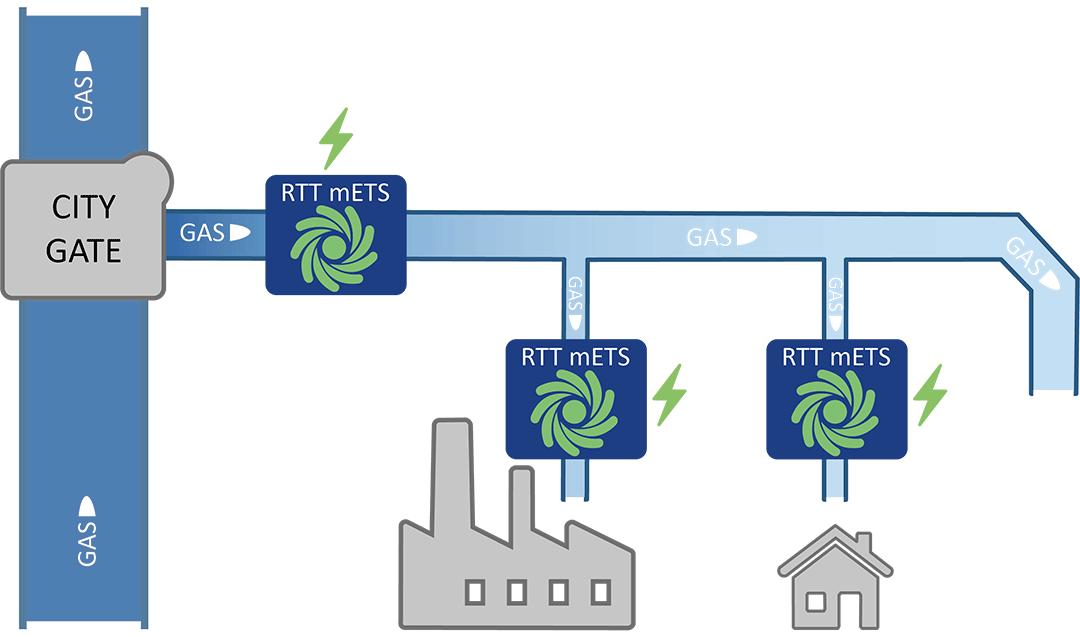

A single mETS turbine only takes up about one cubic foot of space and generates up to 1kW of power using only a small amount of excess gas pressure, as little as 60 psi. Multiple turbines can be smartly operated in parallel to generate even more power where needed.

GREENHOUSE GAS IMPACT

HOW IT WORKS

RTT’s mETS uses only the flow of natural gas (or other available gases with a pressure differential) to generate electricity. Because there is no combustion, mETS systems are incredibly reliable, even in extremely harsh environments.

RTT’s mETS can also be installed for a fraction of the initial cost of TEGs and solar arrays. Moreover, the mETS is designed to operate continuously, 24 hours a day, even under the extreme conditions commonly found in remote environments.

The low installation and maintenance costs associated with the mETS enables these systems to pay for themselves in short order, allowing remote facilities to enhance operations while also maximizing profits.

Excess gas pressure is

used to generate power.

The gas is returned to

the system or the pipeline

from where it originated.

APPLICATIONS

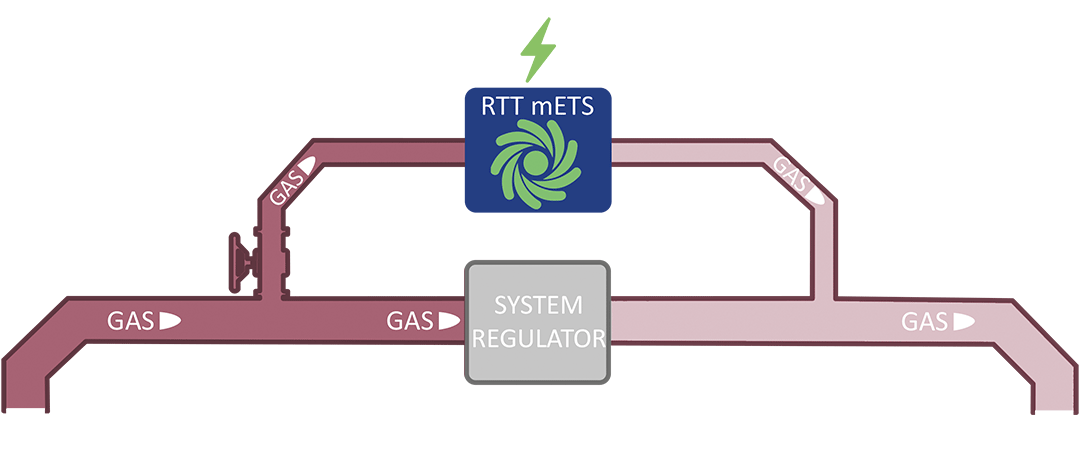

Flowline Bypass

Installed in parallel with a flowline, the mETS diverts a small stream of gas through the turbine to generate electricity, then returns it to the system at a slightly lower pressure

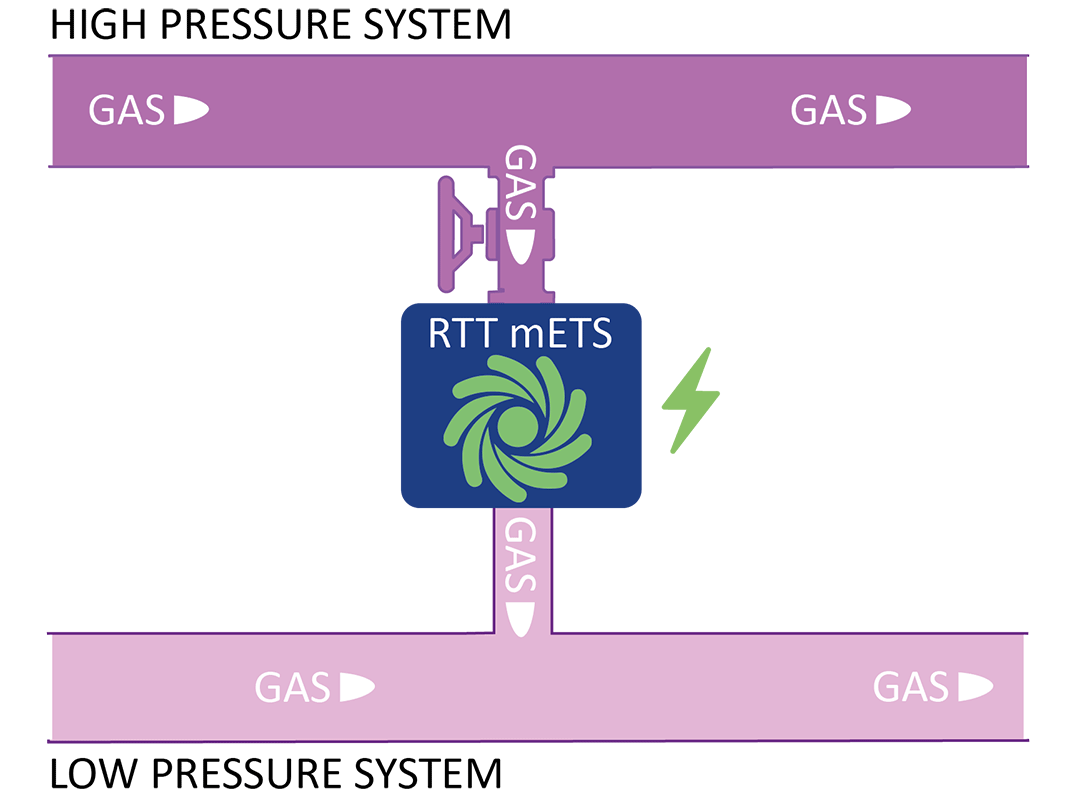

Dual-Pressure

Pressure Step-Down

RTT’s mETS turbines can be installed at strategic points in gas distribution networks to harvest the energy in pressure let-downs that would otherwise be wasted.

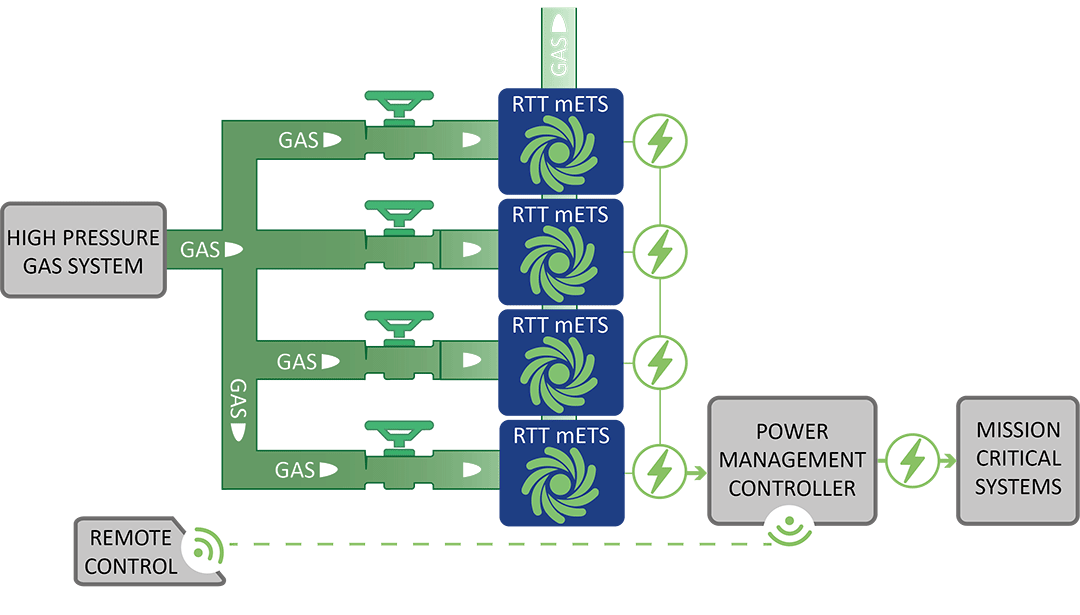

MULTI-TURBINE CONFIGURATION

RTT’s modularity and smart electronics allows gas flow to be managed to multiple turbines, instantaneously matching electric power demand.

COST EFFECTIVE

COST EFFECTIVE

RTT turbines are low CAPEX & OPEX with opportunity to harvest clean energy.

RELIABLE

RELIABLE

The high-quality, extreme condition resistant turbines require low maintenance (≥ 5years).

MODULAR

MODULAR

The unique RTT mETS design offers a small footprint (≤ 1Cu Ft) and the ability to run multiple turbines in parallel offering scalable power on-demand.